The Redesign Capsule: Exploring Remanufacture with Miriam Borcherdt

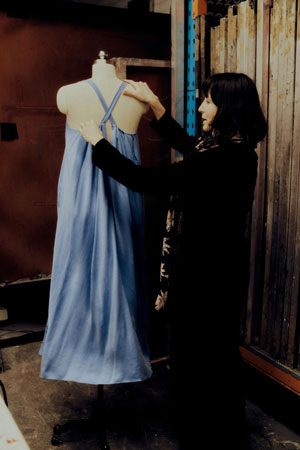

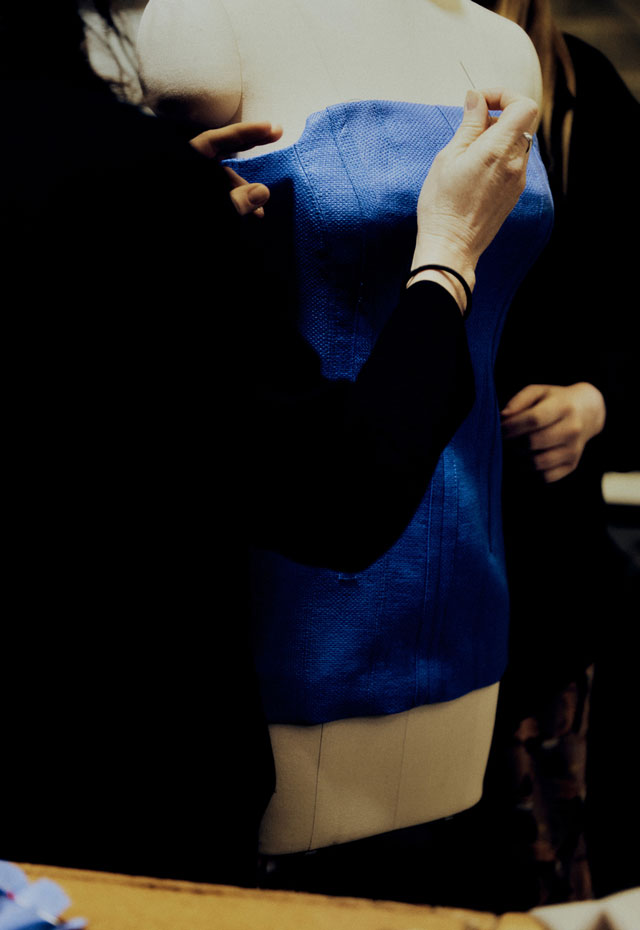

Miriam Borcherdt is a fashion designer and researcher at RMIT. As part of her PhD, titled “RE-kin-DLE”, she is exploring how the redesign and remanufacture of unsold garments can help transition fashion businesses to a circular model.

In collaboration with Miriam and local textile businesses, we’ve created a range that has been reworked from past-season designs. We spoke with Miriam about the potential for fashion businesses to embrace remanufacturing and how the project learnings could shape design decisions in the years to come.

First of all, can you explain to us what circularity means when we’re talking about fashion?

In a linear system, basically we take, we make and we dispose of garments. When garments are not sold, that can represent the end of that garment’s full value. Circularity stands in opposition to a linear system. In a circular system, you retain responsibility and ownership of garments throughout that whole lifecycle, and so through remanufacturing, you can cycle them back into the design and retail phases. The intention behind circularity is to bring materials, garments and products back into use.

A lot of people think circularity is mainly recycling at the end of a garment’s life, but in the circular system, recycling is really the last stopgap solution when all the other circular systems have failed. There is a place for recycling garments in the circular model, but it is actually incredibly difficult because garments are very complex: they’re made out of different materials, the fibres are mixed from natural to synthetic, there are zippers, buttons, labels. There are a lot of things that can’t be recycled and turned back into fibre.

Circularity looks at solutions that try to reduce waste, reduce raw material flowing in, extend the garment lifecycle and basically avoid waste going out.

Tell us about the CR x RE-kin-DLE collaboration.

The collaboration started as part of my PhD research at RMIT, but it also came from a long interest that I've had in my own design business and practice around sustainability. I approached Country Road to be a partner in this research project to see if they would be interested in exploring remanufacturing within their own supply chain and testing—piloting, really—what is an emerging and quite new method of fashion production. I felt that Country Road was a great partner for this because of their existing work in circular design, such as the Towards Circularity range, and their partnership through The Country Road Climate Fund.

I basically worked with the team at Country Road from the beginning. The project involved looking at the broader systems that are being used within Country Road and the opportunities to tap into the existing network of local suppliers, bring in new suppliers and find new processes that could foster circular practices like remanufacturing. So it was about building capacity within Country Road, developing new systems and a lot of problem-solving.

As garments for redesign were sourced from our outlet store, not all sizes are represented across all styles. The Country Road x RE-kin-DLE collection is available in limited numbers online and at our South Yarra and Sydney City stores.

Shop the story

What is the main aim of the collaboration? What are you aiming to achieve?

The main aim was to test remanufacturing techniques on surplus stock to explore circular solutions across the supply chain, and to encourage more circular thinking around fashion production. The world is overproducing fashion and Australia actually has the highest per capita consumption of garments in the world—and by a lot, not just by a little bit. So we need to think about strategies that make better use of resources all along the way, such as remanufacturing.

Remanufacturing doesn’t work with all types of garments because if you’ve got a very low quality product, it’s not worth the investment to redesign it. But Country Road has a high quality product where longevity is planned in from the beginning, so remanufacturing is an option. Remanufacturing is basically a strategy of making garments from existing garments rather than from raw materials. From a design perspective it’s not unlike other types of design processes: you develop a solution that’s targeted to the garments you have and try to rethink them to give them a new life.

What were some of your biggest learnings from the collaboration?

The project was about testing new ideas and piloting new products and processes. Some of the learnings will enable Country Road to design differently at the production stage so that remanufacturing is possible down the track. We very much allowed ourselves to test knowing that not everything was going to work. I think it really illustrated for everyone involved how collaborative this process needs to be and how important it is to bring everyone in early on.

If we're going to get serious and scale circularity, I think it is really important to allow for design to consider these new ways of making as an opportunity rather than a barrier.

It's really put the focus on the bigger picture. Often as designers, we focus on the details and the single individual product, whereas actually, this project made it so clear that it is so much about the broader system that fashion is a part of.

This project is part of Country Road's ongoing circularity journey, including initiatives such as Fashion Trade—a longstanding partnership with Red Cross to keep wearable garments in use—and Towards Circularity, an ongoing range made using 30% recycled cotton sourced from Country Road off-cuts and factory seconds. In 2024, Country Road collaborated with social enterprise HoMie to reimagine past-season sweats into a limited-edition range, and joined Seamless, Australia’s first clothing stewardship scheme.

Shop the story